Features

- Ideal for metalworking applications such as machining and deburring.

- Various type of head shapes and cutting styles are available for wide range of applications.

Applications

| cut styles / materials |

s cut |

k cut |

d cut |

d-max cut |

c cut |

alu cut |

s-inox cut |

d-steel cut |

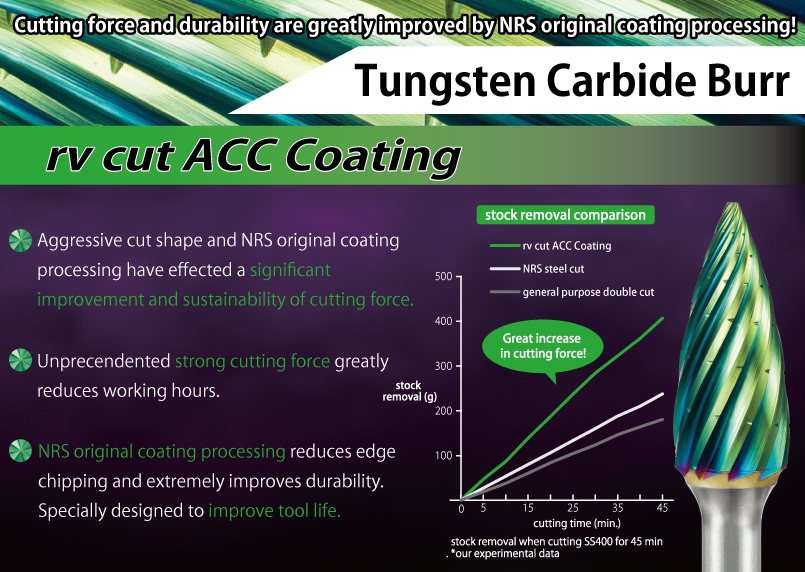

rv cut |

|---|---|---|---|---|---|---|---|---|---|

| Features | produces scratch free surface | provides excellent surface finish for hard materials | universal cutting style with high cutting action | for fast metal removal | small teeth works well for high tensile steels | for use on aluminium and non ferrous metal | cutting force higher than conventional product “s-cut” | cutting force higher than conventional products “d-cut” and “d-max cut” |

cut shape with strong cutting force and durability |

| steel | ● | ○ | ● | ● | ● | ● | ● | ● | |

| hardened steel | ○ | ● | ○ | ○ | ○ | ○ | |||

| stainless steel | ● | ● | ● | ○ | ● | ● | ○ | ● | |

| cast iron | ● | ○ | ● | ● | ○ | ○ | ● | ○ | |

| titanium | ● | ○ | ● | ○ | ○ | ○ | |||

| nicket | ● | ○ | ● | ○ | ○ | ○ | |||

| copper / copper alloys |

● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| aluminium | ● | ○ | ○ | ||||||

| plastics | ● | ||||||||

| cermet | ○ | ● |

Descriptions

Specifications

| A.Cylinder without End Cut |

B.Cylinder with End Cut |

C.Ball Nose Cylinder |

D.Ball | E.Oval |

|---|---|---|---|---|

Product Code Product Code |

Product Code Product Code |

Product Code Product Code |

Product Code Product Code |

Product Code Product Code |

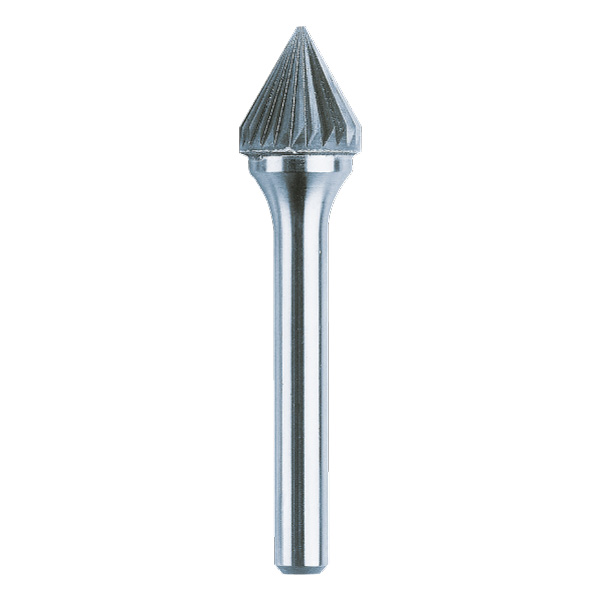

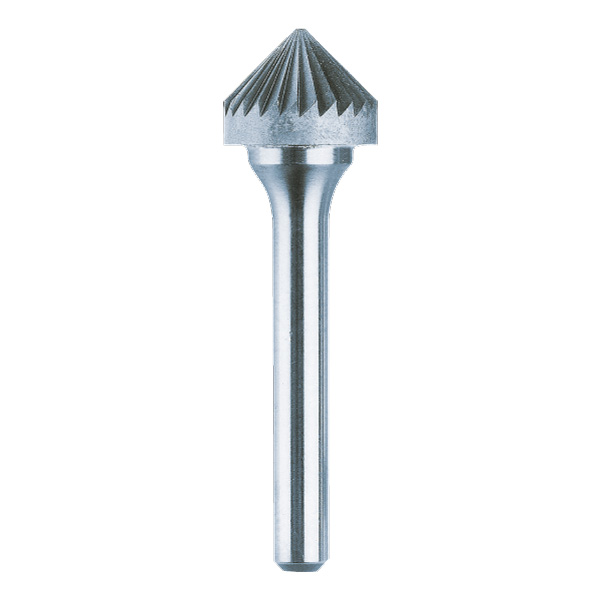

| F.Ball Nose Tree | G.Tree | H.Flame | J.60 Degree Countersink |

K.90 Degree Countersink |

Product Code Product Code |

Product Code Product Code |

Product Code Product Code |

Product Code Product Code |

Product Code Product Code |

| L.Ball Nose Cone | M.Cone | N.Inverted Cone | R.Rim | Long Series Burrs |

Product Code Product Code |

Product Code Product Code |

Product Code Product Code |

Product Code Product Code |

Product Code Product Code |

Article

Package

d cut/d-max cut

c cut

※Old package

d cut/d-max cut

c cut

Recommendations for Proper Use

Precautions

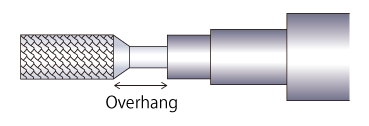

1.Fix the maximum length of burr in the collet.

⇒To prevent radial runout and shank distortion.

2.Do not apply excessive pressure on the burr.

⇒It may cause the problems such as shank distortion, radial runout, tooth chipping and head separation due to overheat.

※Workpiece is ground by the rotation speed, there is no need to bear down on the burr.

3.Always operate the burr within the recommended speed range.

*For max overhang of 10mm

| steel stock | Head Diameter | ||||

|---|---|---|---|---|---|

| 3mm | 6mm | 10mm | 12mm | 16mm | |

| steel | 60,000~ 90,000 |

45,000~ 60,000 |

30,000~ 40,000 |

22,500~ 30,000 |

18,000~ 24,000 |

| hardened steel | 60,000~ 90,000 |

30,000~ 45,000 |

19,000~ 30,000 |

15,000~ 22,500 |

12,000~ 18,000 |

| stainless steel | 60,000~ 90,000 |

30,000~ 45,000 |

19,000~ 30,000 |

15,000~ 22,500 |

12,000~ 18,000 |

| cast iron | 45,000~ 90,000 |

22,500~ 60,000 |

15,000~ 40,000 |

11,000~ 30,000 |

9,000~ 24,000 |

| titanium | 60,000~ 90,000 |

30,000~ 45,000 |

19,000~ 30,000 |

15,000~ 22,500 |

12,000~ 18,000 |

| nickel | 60,000~ 90,000 |

30,000~ 45,000 |

19,000~ 30,000 |

15,000~ 22,500 |

12,000~ 18,000 |

| copper / copper alloys | 45,000~ 90,000 |

22,500~ 60,000 |

15,000~ 40,000 |

11,000~ 30,000 |

9,000~ 24,000 |

| alumium | 30,000~ 90,000 |

15,000~ 65,000 |

10,000~ 50,000 |

7,000~ 35,000 |

6,000~ 25,000 |

| plastics | 30,000~ 90,000 |

15,000~ 65,000 |

10,000~ 50,000 |

7,000~ 35,000 |

6,000~ 25,000 |

| cermet ※A Cermet is a material which solidfied metal compound by metal. |

60,000~ 90,000 |

30,000~ 45,000 |

19,000~ 30,000 |

15,000~ 22,500 |

12,000~ 18,000 |

(min-1)

Lower the rotational speed, when the overhang exceeds 10mm.

⇒Improper operating speed may cause the problems desclibed below.

Running burr too slow will result in low stock removal and tooth chipping.

Running burr too fast will result in shank distortion or head separation caused by overheat.

※Refer the following chart, if you cannot find the head diameter in the above table.

4.Do not sink the burr to more than one-third of its periphery

⇒It may cause burr skipping.

5.Do not contact the burr with two point of work piece.

⇒It may cause burr skipping.

Special care should be taken with cylinder without end cut, cylinder with end cut, inverted cone and rim shaped burr.

6.Do not drop or allow impact.

⇒It may cause tooth chipping.

Select the appropriate tooth shape, cutting style snd size for the application.

Safety Notes

Use the following protective clothing during work.

![]()

For your safety, carefully read the precautions and the manual for tools before use.

※Our products are performed adequate inspections for brazing part and radial runout.