Features

“METARIDGE” is a word made from “metal + bridge”.

As the word suggests, the abrasive grains (diamond) are bridged through the metal and firmly fixed to the base metal. (NRS original electrodeposition technology)

* “METARIDGE BURR” is commonly referred to as “electroplated diamond bur”.

Outstanding grinding force that can remove scab in one go.

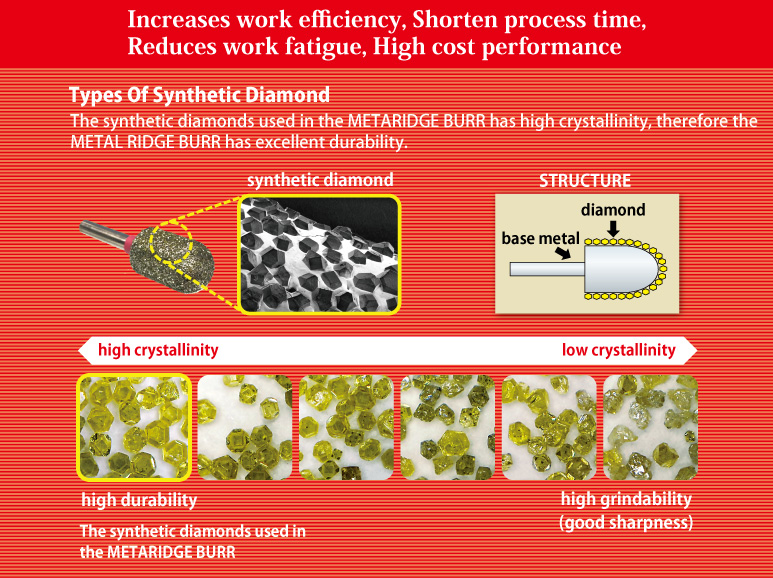

Diamond, which is about 3 times harder than general abrasive grains (alumina), is constantly exposed on the surface without detachment. Therefore, grinding “scabs” or “burnt-on sand” can be very easy.

Unlike the conventional wheels, you don’t need to use force results in reduced work fatigue and improved workability.

Unrivaled durability

The METARIDGE BURR has overwhelming durability compared to conventional mounted wheels, because diamonds which are an extremely hard substance, are firmly fixed to the base metal by NRS original electrodeposition technology.

No deformation, wear and blade chipping

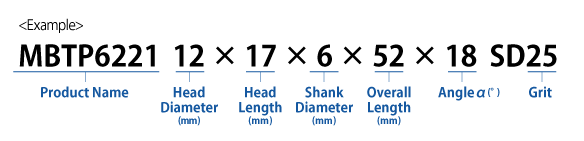

Descriptions

Specifications

| Shank Diameter 6mm |

Shank Diameter 3mm |

|---|---|

Product Code Product Code |

Product Code Product Code |

- The shapes not lited here, we accept small quantities as custom-made products.

Please contact our sales person for ball nosed cylinder bur with screw and flat cylindrical wheel. - Specifications (including design) may change without notice.

Article

Package

Recommendations for Proper Use

Suitable materials

METARIDGE BURR is not suitable for use on ferrous materials such as general steel and stainless steel.

Precautions

1. Insert the shank of METARIDGE BURR into the collet of the hand grinder as far as it will go.

Red tube is for preventing some products from biting into R portion.

2. Do not apply excessive pressure on the burr.

⇒Diamonds are extremely hard, sufficient grinding force can be obtained without excessive pressure. When the temperature gets high, the hardness will be impaired and the grinding force and durability will decrease.

⇒It may cause the problems such as shank distortion, radial runout and breakage, due to overheat.

3. Use the product within maximum operating speed.

⇒Lower the rotational speed, when the overhang exceeds 10mm.

4. Do not sink the burr for more than one third of its periphery.

⇒Diamonds will be overheated and the hardness will be impaired.

⇒It may cause burr skipping.

5. Do not contact the burr with two points.

⇒It may cause burr skipping.

6. Do not drop or allow impact.

Safety Notes

![]()

HOW TO GRIND EFFICIENTLY

Deliver maximize performance of diamond tool by light grinding without force.

* Do not put your weight on the tool. The tool heats up in a short time when it is overloaded.

⇒Shorten the continuous operating time to avoid overheat the diamond tool.

⇒Minimize heat generation and keep good grindability by moving it without pressing it strongly on one place.