- Three Factors of Grinding Wheels

- Features of Grinding Wheels

- Mechanism of Grinding Wheels

- Troubleshooting of Grinding Problem

Three Factors of Grinding Wheels

These three factors enable grinding wheels to grind, polish and cut.

| Abrasives | Each abrasive becomes edge and able to grind workpiece. Abrasives are fallen off when these are worn down and lost sharpness, then these expose new cutting edges constantly (Self sharpening). |

|---|---|

| Binder, Bond | Bond combines and holds the abrasives together. The quality of wheels is controlled by the type and/or compounded amount of bond. |

| Pore | Pore is a space of between abrasives. Shavings fall in the pores and are discharged while the rotations of wheel. Grinding wheel does not work without pores. |

Features of Grinding Wheels

- Abrasive grain is harder than workpiece.

- Abrasives are fallen off when these are worn down and lost sharpness, then these expose new cutting edges constantly.

- Grinding wheels have countless edges and depth of cut is low but these provide fast grinding speed, high performance and fine finish.

- Most of heats generated by operations are absorbed into workpiece.

Mechanism of Grinding Wheels

*Abrasive grains expose new cutting edges constantly; this is a unique feature of grinding wheels called “self sharpening“.

Troubleshooting of Grinding Problem

Have you ever experienced troubles as described below?

| Glazing | Abrasives on wheel face are lost sharpness. Wheel has shiny appearance and feels slick. |

|---|---|

| Clogging | Shavings or worn grains lodged in wheel pores. |

| Shedding | Abrasive grains drop before wearing down. |

If any of such troubles appears, please check the following conditions.

- Operating speed (Be sure the operating speed is no higher than the speed marked on the wheel.)

- Dressing (expose new cutting edges = abrasives) method etc.

*If there is no improvement after changing grinding conditions, please reselect grinding wheels.

-

Ⅰ. Why grinding wheel is able to grind?

-

Ⅱ. Manufacturing Process of Grinding Wheels

-

Ⅲ. What is abrasive grain (abrasives)?

-

Ⅳ. What is binder (bond)?

-

Ⅴ. What is peripheral velocity?

-

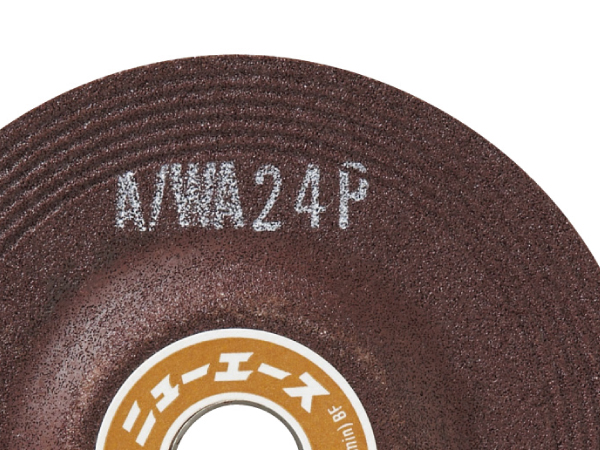

Ⅵ. Indication of Grinding Wheel

-

Ⅶ. Handling and Storage Method of Grinding Wheel

-

Ⅷ. Inspection and Trial Run of Grinding Wheel