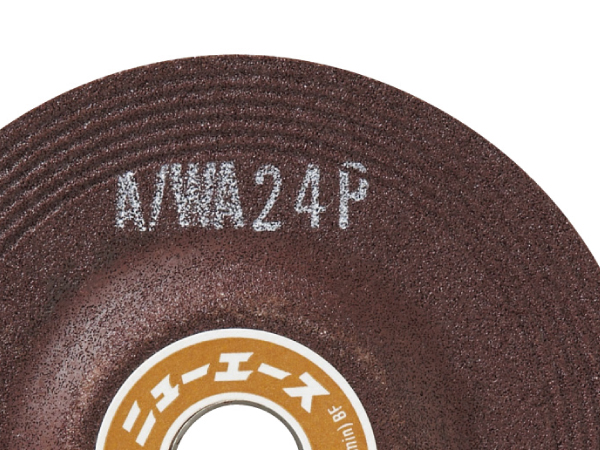

Indication method

Grinding wheels are subdivided into thousands of different types.

The wrong choice of grinding wheels may result in an accident, it’s important to understand the indication method.

| Example of indication 1 | Example of indication 2 | |

|---|---|---|

| 1. Configuration | Type27 center depressed wheel | Type1 flat wheel |

| 2. Profiles | ― | A |

| 3. Dimension | 180×6×22 | 205×19×25.4 |

| 4. Abrasive grain | A | WA |

| 5. Grit | 36 | 60 |

| 6. Grade | P | K |

| 7. Structure | ― | 7 |

| 8. Bond | BF | V |

| 9. Classified code | 3 | 1 |

| 10. Maximum operating speed | 72m/s(4,300m/min) | 33m/s(2,000m/min) |

Meaning of indication

1. Configuration

There are many kinds of wheel shapes, the working surface of each wheel are different.

Use of the surface that is not a working surface will result in accident and is banned by the law.

2. Profiles

Profiles of grinding wheel are indicated by letters. (Only applied to Type1 straight wheel.)

3. Dimension

The grinding wheel size is indicated by the dimensions of the outside diameter(mm)*wheel thickness(mm)*hole diameter.

The size of available wheel is marked on the grinder, make sure to use wheel with the correct size.

4. Abrasive grain(Basic Knowledge of Grinding Wheel Ⅲ)

The two abrasive materials most commonly used nowadays are aluminum oxide and silicon carbide.

The following helps select the wheel which is suitable for materials of workpiece and grinding condition.

5. Grit(Basic Knowledge of Grinding Wheel Ⅲ)

Grit is determined by a screening process on the number of holes per square inch in the screen. The higher the number,the finer the abrasives.

6. Grade

This letter denotes the hardness of the grinding wheel.

The letters A to Z characterises the degree of hardness with A referring to the softest and Z as the hardest.

For grinding hard materials, a soft wheel and for grinding soft material, a hard wheel is chosen.

7. Structure

The porosity determines the percentage of bulk volume of pores in unit volume of grinding wheel, there are wheels of open and close porosity. ( No indication for center depressed wheel)

8. Bond(Basic Knowledge of Grinding Wheel Ⅳ)

Bond is the material holding abrasives together and is usually either ‘V’ (Vitrified) or ‘B’ (Resinoid).

9. Classified code

Each manufacturer classifies the bond into the several types according to the application and use own classified code for products.

10. Maximum operating speed(Basic Knowledge of Grinding Wheel Ⅴ)

Maximum operating speed is the highest speed for ensuring safe operation. User must run the machine at or below the speed.

There are many kinds of grinding wheels, understanding of the indications helps to select the proper wheel.

-

Ⅰ. Why grinding wheel is able to grind?

-

Ⅱ. Manufacturing Process of Grinding Wheels

-

Ⅲ. What is abrasive grain (abrasives)?

-

Ⅳ. What is binder (bond)?

-

Ⅴ. What is peripheral velocity?

-

Ⅵ. Indication of Grinding Wheel

-

Ⅶ. Handling and Storage Method of Grinding Wheel

-

Ⅷ. Inspection and Trial Run of Grinding Wheel