Variety of Manufacturing Method

There are many different kind of manufacturing methods depending on bonds. Our products are produced with resinoid bonds which is safe and used in many industries.

| Bond Type | Code | Major Components | Firing Method / Temperature | Applications | Features |

|---|---|---|---|---|---|

| Vitrified | V | Feldspar / Soluble Clay |

Continuous kiln / Bell kiln / Downdraft kiln 1200-1350°C (2192-2462°F) |

Machining, |

●Use feldspar and/or soluble clay as binder and bake at high temperature of 1300 degrees C after complete drying. ●The most common manufacturing method. ●Easy to adjust grade and structure. |

| Resinoid | B・BF *BF=Resinoid and Reinforced |

Phenol resin, other artificial resins |

Low temperature electric oven, around 200°C (392°F) |

Rough grinding, Free-hand grinding, Cutting, Machining, Lapping |

●Use synthetic resin as binder and harden at low temperature of 200 degrees C. ●Springy and resistant to high speed rotation. ●There are wide variety of wheels according to purposes. *Our grinding wheels are resinoid bonded wheels which are produced by this method. |

| Rubber | R | Natural / synthetic rubber, Sulfur | Low temperature electric oven, around 180°C (356°F) | Cut off / Centerless grinding wheel |

●Use natural or synthetic rubber as binder and harden at low temperature of 180 degrees C. ●Springiest. ●Ideal for thin wheel. |

| Silicate | S | Silicate soda (water glass) |

Downdraft kiln 600-1000°C (1112-1832°F) | Sharpening, surface grinding |

●Use silicate soda as binder and harden at low temperature. Ideal for sharpening and polishing of wood saw. ●Silicate soda acts as lubrication. ●For soft grade wheels. |

| Magnesia | O | Magnesium oxychloride cement | Unfired wheel, harden at ordinary temperature. | Sharpening, surface grinding. |

●Use kind of cement as binder and harden at ordinary temperature. Reduce effect of grinding heat, ideal for surface grinding of thin materials. ●Provide good grinding performance with low speed. |

| Shellac | E | Shellac (natural resin) |

Low temperature electric oven, around 170°C (338°F) | Tool grinding, Lapping |

●Use natural resin as binder and harden at low temperature after compression molding. Ideal for low speed lapping. ●For soft grade wheels |

Manufacturing Method of Grinding Wheels

Manufacturing process of our main products “resinoid bonded wheel” are introduced below.

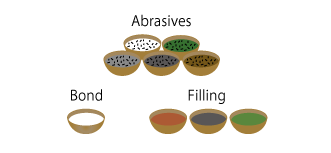

Raw materials

・Use Abrasive grains, filling and bond.

・Compounding ratio varies with each product.

What is filling?

Except abrasives and bond, grinding wheel contains many compounds as filling.

There are many purposes of adding filling, such as performance increase or coloring (green, red or black etc.).

Mixing the ingredients

All materials are dried after mixing thoroughly.

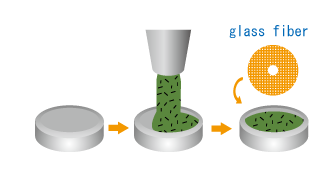

Molding

・Forming in mold.

・Insert special glass fiber (glass cloth) as reinforcement during the molding process.

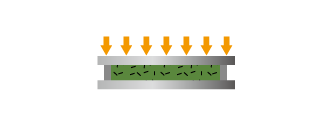

Pressing

Demold after pressing.

Firing

・Fire wheels completely at around 200 °C (392°F)

・Firing is a very important process that influence its grade and quality.

Inspection

We inspect all products to keep high quality and safty.

Test

Perform many test for maintaining high quality and safety of the products.

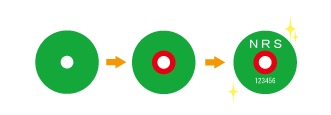

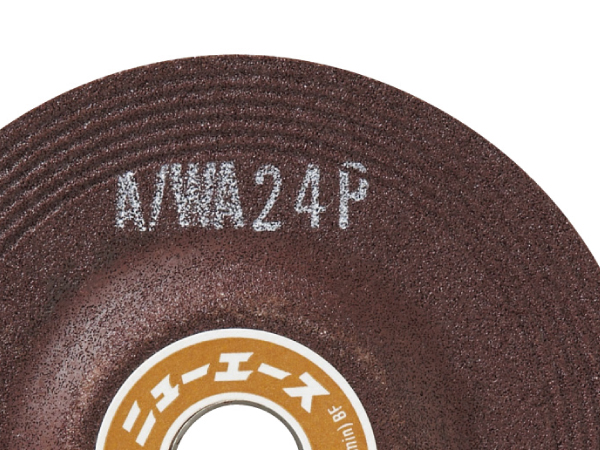

Indications

Print and stick label on the products.

Packaging

Packaging products in boxes.

Shipping

Accepted products are shipped to customers.

Our products are manufactured by the above processes.

We are committed to offering safe and good quality products to customers.

-

Ⅰ. Why grinding wheel is able to grind?

-

Ⅱ. Manufacturing Process of Grinding Wheels

-

Ⅲ. What is abrasive grain (abrasives)?

-

Ⅳ. What is binder (bond)?

-

Ⅴ. What is peripheral velocity?

-

Ⅵ. Indication of Grinding Wheel

-

Ⅶ. Handling and Storage Method of Grinding Wheel

-

Ⅷ. Inspection and Trial Run of Grinding Wheel