Role of Bond

The bond holds abrasives together. Commonly phenol resin is used to resinoid grinding wheels.

Type of Resin

Resin is a type of plastic. There are 2 types of resin; thermosetting resin and thermoplastic resin.

Phenol resin is classified into thermosetting resin.

| Type | Comment | Resin |

|---|---|---|

| Thermoplastic resin | Thermoplastic resin softens when heated and becomes moldable. It is molded and processed easily. Its heat resistance, chemical resistance and hardness are inferior to thermosetting resin. |

Polyethylene, Vinyl chloride resin, Polypropylene, ABS resin, PET |

| Thermosetting resin | Thermosetting resin hardens when heated and cannot be remolded. It has superior heat and chemical resistance. | Phenol resin, Urea resin, Epoxy resin, Melamine resin, Unsaturated polyester resin, Polyurethane |

Features of Phenol Resin

- Hardened resin has better heat resistance than others.

- High mechanical characteristic (strength).

- Small shrinkage after molding.

- Stable to various solvents and other chemicals.

| Type of Phenol Resin | |

|---|---|

| Form | Liquid, Powder |

| Chemical property | Resol Type, Novolak Type |

The role of bond is to hold the individual abrasives together.

Extra Information – History of Phenol Resin-

In 1872 the German chemist Adolf von Baeyer discovered the resin that results from the hydrochloric acid-catalyzed reaction between phenol and formaldehyde.

About 20 years later, formaldehyde came on the market as medicines and was restudied. As a result, the phenol resin came to be recognized its existence, but was not put to practical use at that time.

In the 1890s phenol and formaldehyde became available as industrial materials and were studied actively.

American chemist Leo Baekeland succeeded in producing hard moldable plastic for the first time. The process patent was filed in 1907, and the product was named “Bakelite”.

“Bakelite” was introduced into Japan by Jyoukichi Takamine who was a friend of Baekeland in 1909, and then Sankyo Co., Ltd. received the patent in Japan at no cost and started producing “Bakelite”.

-

Ⅰ. Why grinding wheel is able to grind?

-

Ⅱ. Manufacturing Process of Grinding Wheels

-

Ⅲ. What is abrasive grain (abrasives)?

-

Ⅳ. What is binder (bond)?

-

Ⅴ. What is peripheral velocity?

-

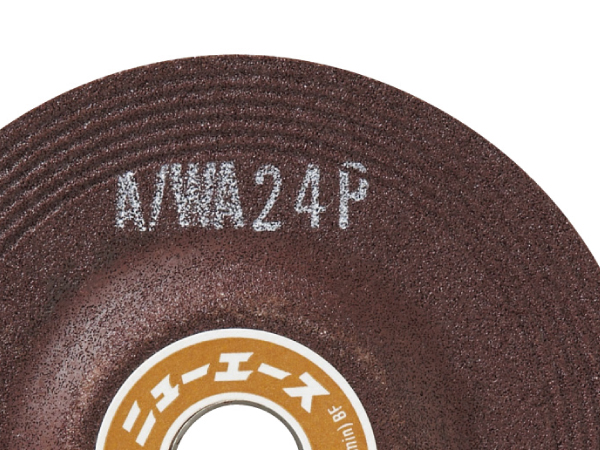

Ⅵ. Indication of Grinding Wheel

-

Ⅶ. Handling and Storage Method of Grinding Wheel

-

Ⅷ. Inspection and Trial Run of Grinding Wheel